Does Non-Destructive Strength Sensing have Muscle?

The question whether ultrasonic measurements of paper stiffness (sonic stiffness) can predict usual paper properties we report every day in our machine test rooms is one that is often asked. The introduction of laboratory measurements for tensile stiffness and orientation angle, have really improved the operation and quality control around the paper machine. The measurement offers a reliable and trustworthy measurement of sonic stiffness in the md and cd and often at various angles and can give indication of the way the fibres are laid down in the sheet allowing control of nasty surprises at the converter like warp and curl. Many people believe that is enough and well done.

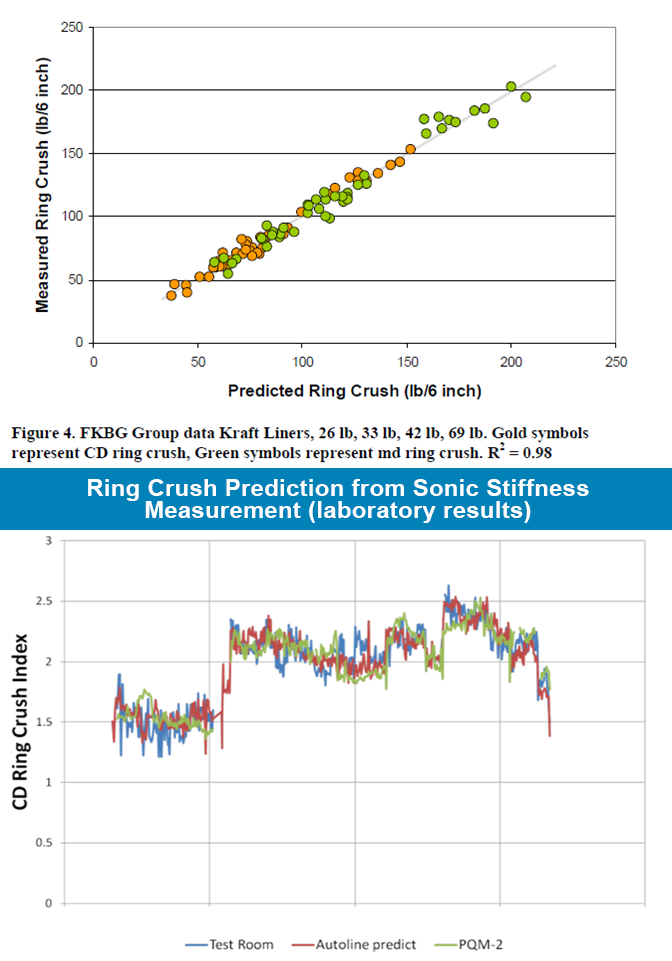

Ring Crush Prediction from sonic stiffness measurement (laboratory results)

After a few decades of believing that on-line non-destructive measurement could potentially replace the traditional paper strength tests, Gary Baum eventually succumbed to the inevitable and stated in the 1980’s that: “we might never be able to use ultrasonic measurement for predicting strength properties but most likely the measurement will be used as a sensitive gauge of process “health”.

So what was the problem? Firstly, the test measures the stiffness of paper – an elastic property not the usual failure properties that we would measure in the paper machine laboratory like ring crush, compression or tensile strength. So that means to predict tensile strength we need to relate the elastic property – stiffness – to the failure property tensile strength. Can this be done? It turns out it can as long as the character of the fibres do not change too much. Page and later El Housseiny showed that once the character of the fibre changes, say from virgin fibre to recycled fibre – then although the mathematical form of the relationship between the elastic property and failure property is the same, the scaling is not.

So it turns out that the relationships between elastic properties and paper test properties exist but need to be scaled depending upon the fibres used in the paper. Machine parameters like refining, moisture, wet pressing and starch addition are all generally accommodated and properties are reflected by changes in the measured elastic properties.

Need proof? The first plot above shows predicted ring crush against measured ring crush for a large number of US liner board machines. The second plot shows several weeks of on-line measurements used to predict in real time, the ring crush index performance of the machine papers compared to laboratory measurements. I’ll leave it to you to decide.